Introduction to the Langley 425 Baitcasting Reel

When you pick up a Langley 425 baitcasting reel, you’re holding a piece of fishing history. This reel has earned its stripes among serious anglers who value reliability over flashy marketing. Understanding the Langley 425 baitcasting reel schematic isn’t just about fixing things when they break – it’s about getting the most out of every cast.

Many fishermen have discovered that Langley reels punch above their weight class. They might not have the marketing budget of bigger brands, but they’ve built a solid reputation through decades of dependable performance. Whether you’re maintaining your current reel or considering a purchase, this comprehensive breakdown will give you the inside knowledge you need.

Understanding Baitcasting Reel Schematics

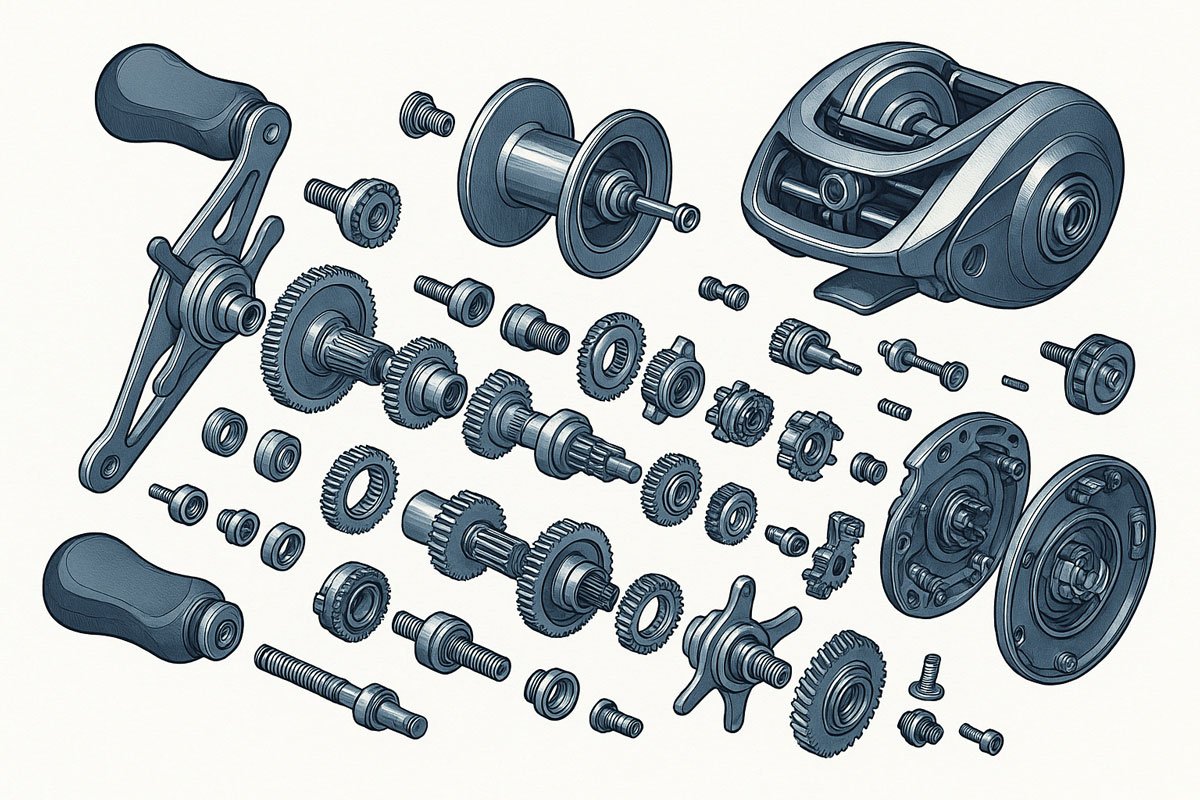

A schematic diagram might look intimidating at first glance, but it’s really just a roadmap of your reel’s anatomy. Think of it as the DNA of your Langley 425 – every screw, spring, and gear has its place and purpose. Once you learn to read these diagrams, you’ll never feel helpless when something goes wrong on the water.

The beauty of understanding schematics lies in the confidence it brings. Instead of guessing which part does what, you’ll know exactly how your reel ticks. This knowledge transforms you from someone who just uses fishing gear into someone who truly understands it.

Langley 425 Core Components Breakdown

External Components

The first thing you notice about the Langley 425 is its solid feel. The reel foot isn’t just a mounting point – it’s engineered to distribute stress evenly across your rod’s reel seat. This attention to detail shows up throughout the external components.

The handle assembly deserves special mention. Unlike some reels that feel flimsy after a season of hard use, the Langley 425’s handle maintains its solid connection. The star drag system sits right where your fingers naturally fall, making pressure adjustments feel intuitive even when you’re focused on fighting a fish.

That thumb bar might seem simple, but its positioning and tension are crucial for smooth casting. When properly adjusted, it becomes an extension of your thumb, giving you precise control over line release.

Internal Mechanism Components

Pop open the side plate of a Langley 425, and you’ll see why these reels last so long. The spool assembly sits on quality bearings that, with proper maintenance, can provide years of smooth operation. The gear train shows thoughtful engineering – each gear is sized and positioned to handle the stresses of serious fishing.

The braking system represents one of the most critical aspects of baitcasting reel design. The Langley 425’s centrifugal brake system uses adjustable friction blocks that respond to spool speed. This isn’t just theory – it’s the difference between a perfect cast and a frustrating backlash.

Detailed Parts Analysis and Functions

Spool and Bearing Assembly

The spool design of the Langley 425 reflects practical engineering choices. The materials balance weight against strength, creating a spool that’s light enough for long casts but tough enough to handle big fish. The bearing placement follows time-tested principles that prioritize longevity over flashy specifications.

Here’s something many anglers overlook: the spool tension knob isn’t just for preventing backlash. Experienced fishermen use it to fine-tune their casting for different lure weights and wind conditions. Master this adjustment, and you’ll cast more accurately than anglers using reels costing twice as much.

Braking System Configuration

The centrifugal brake system in the Langley 425 operates on physics that hasn’t changed since these reels were first designed. As the spool spins faster, centrifugal force pushes the brake blocks outward, creating more friction. It’s elegant in its simplicity and effective in practice.

What sets experienced anglers apart is their ability to adjust these brakes for different situations. Heavy lures in calm conditions might need fewer active brake blocks, while light lures in windy weather require maximum braking. The Langley 425’s system makes these adjustments straightforward once you understand the principles.

Assembly and Disassembly Procedures

Step-by-Step Disassembly Guide

Taking apart a Langley 425 requires patience more than skill. Start with a clean workspace and good lighting – you’ll thank yourself later when you’re putting everything back together. Remove the handle first, then work your way through the star drag and side plate.

Here’s a tip from veteran reel mechanics: take photos as you disassemble. Modern smartphones make this easy, and having visual references during reassembly can save hours of frustration. Pay special attention to spring orientations and gear alignments.

Reassembly Best Practices

Reassembly is where attention to detail pays off. Clean each component thoroughly before installation. A light coat of quality reel oil on bearings and a small amount of marine grease on gears will keep everything running smoothly.

The key to successful reassembly is taking your time with gear alignment. The Langley 425’s gear train is forgiving, but proper mesh is essential for smooth operation. Test each function as you reassemble – it’s much easier to fix problems before everything is buttoned up.

Maintenance and Troubleshooting

Regular Maintenance Schedule

Smart anglers develop maintenance routines that become second nature. After each fishing trip, a quick rinse with fresh water and a wipe-down takes just minutes but adds years to your reel’s life. Monthly deeper cleaning during active seasons keeps internal components in top condition.

Seasonal maintenance is where the schematic really proves its worth. Knowing exactly where each lubrication point is located means you can service your reel thoroughly without guesswork. This proactive approach prevents most problems before they start.

Common Issues and Solutions

Backlash remains the most common complaint with baitcasting reels, but it’s usually a setup issue rather than a mechanical problem. The Langley 425’s brake system is designed to prevent overruns when properly adjusted. Start with maximum braking and gradually reduce it as your casting improves.

Drag problems often trace back to contaminated or worn drag washers. The good news is that replacement washers are readily available and installation is straightforward when you understand the schematic. Jerky or inconsistent drag usually means it’s time for cleaning and fresh lubrication.

Performance Optimization Tips

Upgrading components can transform a good reel into a great one. Ceramic bearings offer noticeable improvements in casting distance and smoothness, though they require more careful maintenance. Carbon fiber drag washers provide smoother, more powerful drag performance than stock washers.

Handle customization might seem cosmetic, but the right handle length and grip style can significantly improve your fishing experience. Longer handles provide more leverage for big fish, while different grip materials can improve comfort during long fishing sessions.

Professional tuning services can optimize your Langley 425 beyond what’s possible with basic maintenance. These services typically include precision bearing alignment, gear timing optimization, and brake system fine-tuning that maximizes performance.

Conclusion

The Langley 425 baitcasting reel schematic reveals the thoughtful engineering behind this dependable fishing tool. Understanding these diagrams empowers you to maintain, repair, and optimize your reel for peak performance. More importantly, it connects you with the mechanical heritage that makes fishing reels like the Langley 425 such enduring pieces of equipment.

Whether you’re troubleshooting a problem or simply want to understand your gear better, the time invested in learning your reel’s schematic pays dividends on the water. The Langley 425 rewards this attention with years of reliable service and the confidence that comes from truly knowing your equipment.