To ensure the longevity of a Duramax Turbo Coolant Hose, it is essential to adhere to recommended maintenance practices. These hoses are vital components in a vehicle’s cooling system, serving as conduits for coolant to keep the engine at an optimum temperature. Regular inspections and timely replacements prevent overheating and ensure the cooling system operates effectively.

Maintaining the correct Duramax coolant type is also a key factor in promoting the durability of the hose. The use of appropriate coolants and additives can prevent corrosion and deterioration of the hose material. Alongside the choice of coolant, appropriate clamping force and avoiding sharp bends during hose installation will mitigate the risk of leaks or failures. Additionally, implementing a holistic approach to vehicle maintenance, including inspection of related components such as the radiator and water pump, will further augment the hose’s service life and overall engine health.

Key Takeaways

- Regular inspections and replacements are essential for hose longevity.

- Correct coolant and additives preserve hose integrity.

- Holistic vehicle maintenance supports cooling system efficiency.

Essential Maintenance for Duramax Turbo Coolant Hose

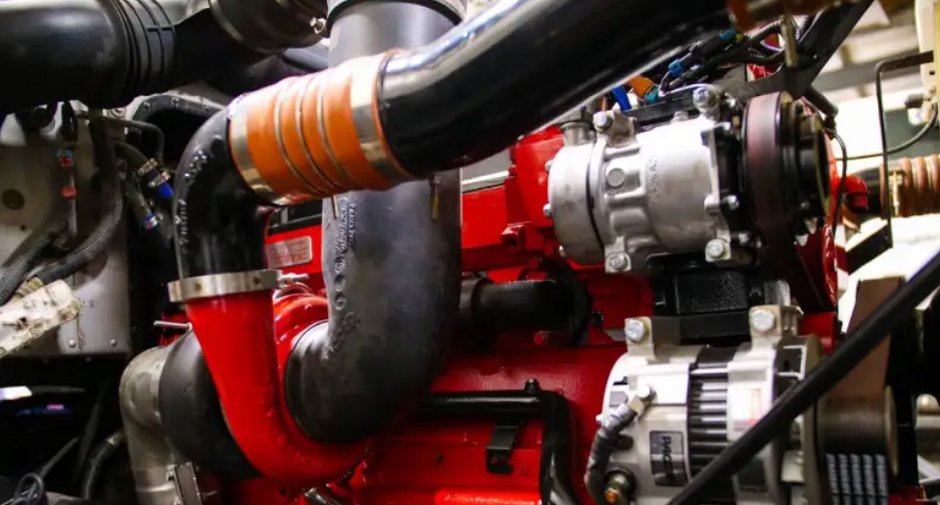

Ensuring the durability and performance of a Duramax engine requires vigilant attention to the turbo coolant hose. The longevity of these hoses is critical to maintaining the engine’s cooling system.

Regular Inspection and Replacement

It’s imperative to conduct regular inspections of the Duramax turbo coolant hose. Check for signs of wear, such as fraying, cracks, or coolant leaks. The material of the hose can degrade over time, leading to potential failures. Clamps and fittings should also be examined for corrosion or damage, and replacement should occur as necessary. Use hoses like Chevy GM Duramax Coolant Hoses & Pipes that meet OEM specifications to ensure compatibility and durability. The hoses typically have a specific measurement, often 3/8″ in diameter. Note the hose’s part number for quick reference during replacements.

Proper Coolant Selection and Change

Selecting the right coolant is vital for the proper functioning of the cooling system. Use coolants like ACDelco 10-9243, which are designed to work seamlessly with GM engines. Additionally, adhering to recommended capacities and changing the coolant at prescribed intervals prevents the build-up of contaminants that can cause corrosion. A well-circulated coolant mix supports the water pump in transferring heat away from the engine, minimizing the risk of overheating and hose damage. It’s critical not just to top off but to completely change the coolant to maintain the health of the entire system.

Complementary Vehicle Maintenance for Overall Longevity

Maintaining the longevity of a vehicle extends beyond individual component care. It requires a comprehensive approach to servicing integral systems and replacing critical fluids regularly.

Full System Check and Fluid Replacement

Regular system checks are crucial for identifying issues before they worsen. During these checks, essential fluids such as engine oil, coolant, and transmission fluid should be evaluated for quality and level. Especially important is the Duramax coolant type, which must be compatible with the system to prevent corrosion and overheating. For the cooling system, a full flush and replacement of the coolant at prescribed service intervals ensure the engine remains at an optimal temperature.

- Engine Oil and Oil Filter: Change every 3,000 to 5,000 miles to ensure engine lubrication and longevity.

- Transmission Fluid: Replace according to the manufacturer’s recommendations to maintain smooth shifting.

- Coolant: Check routinely and replace every 30,000 miles or as recommended.

- Brake Fluid: Inspect and replace to maintain effective braking performance.

Additional Maintenance Considerations

Beyond fluid management, certain components require regular inspections and replacements to support longevity.

- Fuel System: Changing the fuel filter can protect the engine from contaminants.

- Air Intake: A clean engine air filter maximizes airflow and engine efficiency.

- Tires: Tire rotation extends their life and ensures even wear.

- Belts: Inspect for wear and tension, and replace as necessary.

- Bolts: Check and tighten any bolts related to important components like the cooling system to avoid leaks or failures.

- Differentials and Transfer Case: Differential and transfer case fluid levels are often overlooked but essential for the health of the drivetrain.

Other fluids and components, such as diesel exhaust fluid and steering components, should be checked regularly. Maintaining these elements helps provide consistent performance and reliability from the passenger side to the drivetrain. Ensuring your Duramax Turbo Coolant Hose is in peak condition for a robust cooling system will prevent overheating and potential engine damage.

Conclusion

Consistent maintenance is crucial to uphold the integrity and functionality of a Duramax Turbo Coolant Hose. The primary practices include regular inspections for wear and tear, timely replacement of hoses nearing the end of their service life, and ensuring appropriate clamp tightness to prevent leaks. Where issues are detected, swift action should be taken to remedy any faults to secure the continued performance of the engine’s cooling system. These steps are instrumental in maximizing the hose’s longevity and maintaining engine efficiency.