In the fast-paced world of computer manufacturing, precision and efficiency are paramount. As the demand for smaller, faster, and more powerful computing devices continues to grow, manufacturers are increasingly turning to advanced technologies to streamline production processes and enhance product quality. Among these technologies, servo drives play a critical role, offering unparalleled precision in the automation of manufacturing processes. This article delves into the application of servo drives in computer manufacturing, examining their impact on production efficiency, precision, and overall industry evolution.

The Role of Servo Drives in Computer Manufacturing

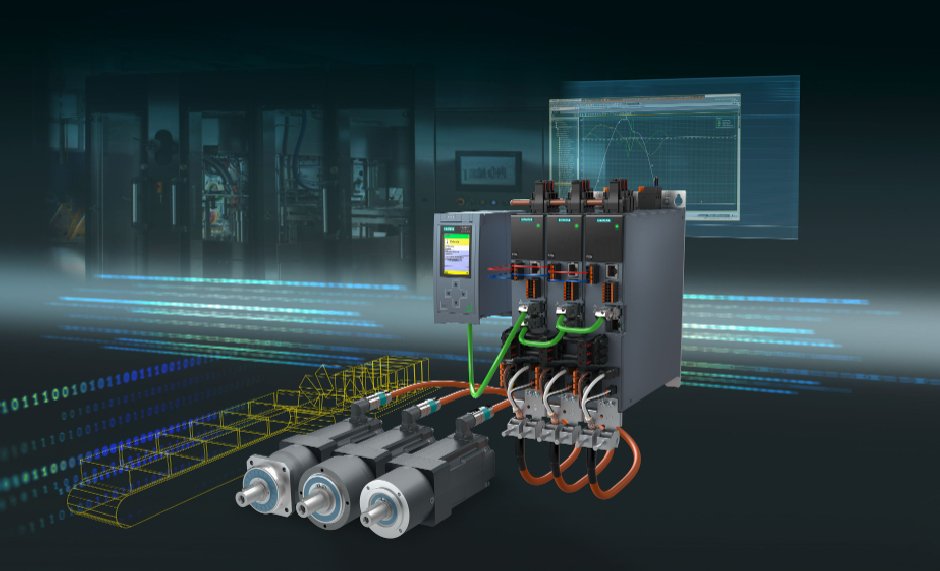

Servo drives are sophisticated electronic devices used to control servo motors, which are employed extensively in automation. In the context of computer manufacturing, servo drives regulate the speed, position, and torque of servo motors with high precision, making them essential for tasks requiring intricate detail and exact movements. Their application ranges from the assembly of tiny electronic components to the precise placement of chips on circuit boards.

Enhancing Precision in Component Assembly

One of the primary benefits of servo drives in computer manufacturing is their ability to enhance precision. Computer components, especially microchips and motherboards, require exact placement during assembly, a task perfectly suited to servo-driven systems. These drives control the movement of robotic arms or conveyor belts with high accuracy, ensuring components are assembled without error. This precision is crucial not only for the functionality of the computers but also for minimizing waste of expensive materials.

Increasing Production Speed and Efficiency

Servo drives significantly contribute to increasing the speed and efficiency of production lines. By optimizing the movement of machinery, servo drives reduce cycle times and increase throughput. In computer manufacturing, where market demand can spike unpredictably—often driven by new software releases or technological advancements—being able to quickly scale production without sacrificing quality is a significant advantage. Servo drives allow for rapid adjustments in production processes, enabling manufacturers to respond swiftly to market needs.

Reducing Downtime and Maintenance Costs

Another advantage of integrating servo drives into computer manufacturing is their impact on reducing downtime and maintenance costs. Servo drives are designed to operate efficiently and with minimal maintenance. They provide detailed feedback about the motor’s performance and health, allowing for predictive maintenance practices. By predicting potential failures before they occur, manufacturers can schedule maintenance without significant disruption to production, thereby reducing downtime and associated costs.

Supporting Miniaturization in Electronics

As computers continue to get smaller, manufacturing processes must adapt to handle increasingly miniature components. Servo drives are integral to this aspect of manufacturing, offering the precision required to assemble small parts reliably. The ability of servo drives to control movements down to the micron level makes them indispensable in the production of laptops, smartphones, and tablets, where compact and efficient design is crucial.

Integrating with Industry 4.0

The rise of Industry 4.0, or the Fourth Industrial Revolution, is characterized by increased automation and data exchange in manufacturing technologies. Servo drives integrate seamlessly into these smart manufacturing environments. Equipped with advanced sensors and connectivity features, servo drives can collect and relay critical production data to centralized monitoring systems. This data integration supports the optimization of the manufacturing process, enhancing not only individual machine performance but also the entire production line’s efficiency.

Challenges and Future Directions

While the benefits of servo drives in computer manufacturing are significant, there are challenges to their broader adoption. The initial setup and integration costs can be high, particularly for manufacturers upgrading from older equipment. There is also a learning curve associated with operating and maintaining these advanced systems, requiring ongoing training for technical staff.

Looking ahead, ongoing advancements in servo drive technology promise even greater precision and efficiency. Future developments could see servo drives with enhanced AI capabilities, enabling them to make real-time adjustments based on immediate feedback from the manufacturing process. Such innovations could further revolutionize the speed and flexibility of computer manufacturing.

Conclusion

Servo drives, like those from Indramat, are proving to be a cornerstone technology in the evolving landscape of computer manufacturing. With their unparalleled precision, efficiency, and integration capabilities, they are not just responding to current demands but are also shaping the future of how computers are made. As manufacturers continue to navigate the challenges of a competitive market, the role of servo drives in ensuring the production of high-quality computing devices quickly and efficiently will undoubtedly expand, further embedding them as a critical component of modern manufacturing solutions.