Acrylic plastic is a synthetic polymer made from a combination of acrylic acid, a monomer, and a comonomer. It is commonly used in a variety of products, such as windows, pipes, and as a replacement for glass. One question that often arises about acrylic plastic is whether or not it is toxic.

In general, acrylic plastic is not toxic. It is not known to cause any harm when it comes into contact with skin or when it is ingested. However, it is important to note that the manufacturing process of acrylic plastic can release fumes that can be harmful if inhaled in large quantities.

In this blog post, I highlight the various uses of acrylic plastic, its toxicity level and alternatives to acrylic ( such as glass, PVC etc) . I will also guide you on how to safely recycle acrylic plastic.

Related Posts

TOP 10 Best Acrylic Fish Tanks in 2023

Sublimation on Acrylic for Beginners

Will Acrylic Paint Stick To Plastic?

What Is Acrylic Plastic Made Of?

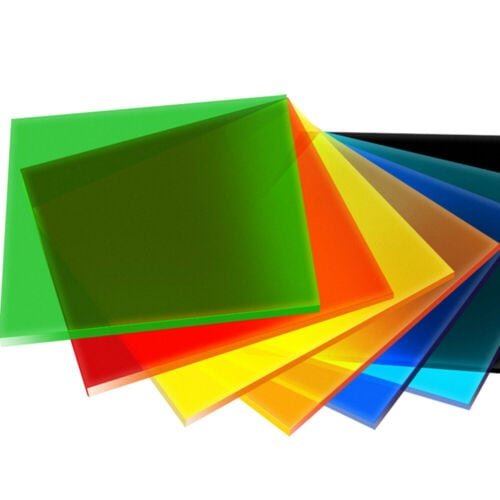

Acrylic plastic, also known as polymethyl methacrylate (PMMA), is made from a combination of acrylic acid and a comonomer, which is a second type of monomer. The resulting polymer is a transparent, rigid plastic that is commonly used in a variety of products, including windows, pipes, and as a replacement for glass.

The manufacturing process for acrylic plastic involves the polymerization of the acrylic acid and comonomer, which results in the formation of long chains of polymer molecules. These polymer chains are then cooled and solidified to create the final acrylic plastic product.

Acrylic plastic is known for its transparency, durability, and versatility, making it a popular choice for a wide range of applications. It is also resistant to weathering and UV light, which makes it a good choice for outdoor use. However, it is not as strong as some other types of plastic and is more prone to scratching.

Uses of Acrylic Plastic

Acrylic plastic, also known as polymethyl methacrylate (PMMA), is a transparent, rigid plastic that has a number of useful properties, including durability, versatility, and resistance to weathering and UV light. These properties make it a popular choice for a wide range of applications.

Some common uses for acrylic plastic include:

- Windows: Acrylic plastic is often used as a replacement for glass in windows, particularly in areas where security and impact resistance are a concern.

- Signs and displays: Acrylic plastic is frequently used in the production of signs and displays, as it is a lightweight and durable material that can be easily molded into a variety of shapes and sizes.

- Pipes: t is also used to make pipes and tubes for a variety of applications, including plumbing, waste water treatment, and industrial piping systems.

- Medical devices: Also, acrylic plastic is often used to manufacture medical devices, such as intravenous (IV) bags, tubing, and respiratory masks, due to its transparency and serializability.

- Automotive components: Most acrylic plastic is used in the production of a variety of automotive components, including headlights, taillights, and instrument panel displays.

- Furniture: Furthermore, acrylic plastic is used to make furniture, such as chairs, tables, and stools, due to its transparency and durability.

- Aquariums: Acrylic plastic is often used to make aquariums and fish tanks, as it is stronger and more impact-resistant than glass.

- Art and crafts: Lastly, acrylic plastic is frequently used in art and crafts, such as modelling and sculpture, due to its versatility and ease of shaping.

Protective coverings: Acrylic plastic is used to make protective coverings, such as sneeze guards and barriers, due to its transparency and durability. Overall, acrylic plastic has a wide range of uses due to its unique combination of properties.

Negatives of Acrylic Plastic?

Some potential negatives of acrylic plastic include:

- Strength: It is not as strong as some other types of plastic, such as polycarbonate. It is more prone to breaking or cracking under impact or stress.

- Scratching: Another downside of acrylic plastic is more prone to scratching than some other types of plastic, which can affect its appearance over time.

- Yellowing: Acrylic plastic is known to yellow when exposed to UV light, which can affect its transparency and overall appearance.

- Flammability: It has a high flammability rating, which means it can burn easily. It should be handled with caution around sources of heat or flame.

- Fumes: The manufacturing process for acrylic plastic can release fumes that may be harmful if inhaled in large quantities. It is important to ensure proper ventilation when working with acrylic plastic.

Recycling Acrylic Plastic

Acrylic plastic, also known as polymethyl methacrylate (PMMA), can be recycled. However, it is important to note that not all recycling facilities have the equipment to process acrylic plastic. Here are some instructions on how to recycle acrylic plastic:

- Check with your local recycling facility to see if they accept acrylic plastic. Some facilities may not have the equipment to recycle acrylic plastic, so it is important to check before attempting to recycle it.

- Clean and dry the acrylic plastic. Remove any dirt, debris, or contaminants from the surface of the plastic. Make sure the plastic is completely dry before proceeding to the next step.

- Remove any non-plastic parts. If the acrylic plastic contains any non-plastic parts, such as metal hardware or rubber seals, these should be removed before recycling.

- Crush or shred the acrylic plastic. Acrylic plastic should be crushed or shredded into small pieces to make it easier to transport and process.

- Transport the acrylic plastic to the recycling facility. Once the acrylic plastic has been cleaned, dried, and crushed or shredded, it can be transported to the recycling facility for processing.

Follow the recycling facility’s instructions. The recycling facility may have specific instructions on how to properly recycle acrylic plastic, such as how to package it or which types of acrylic plastic they accept. Be sure to follow these instructions to ensure that the plastic is properly recycled.

Overall, recycling acrylic plastic is an important way to reduce waste and conserve resources. By following these steps, you can help ensure that your acrylic plastic is recycled in an environmentally-friendly manner.

Related Post: Can You Dye Acrylic Yarn?

Alternatives to Acrylic Plastic

There are a number of alternatives to acrylic plastic that can be used in applications where acrylic plastic may not be the best choice. Some of the most common alternatives include:

- Polycarbonate: Polycarbonate is a strong, transparent plastic that is more impact-resistant than acrylic plastic. It is also more UV stable and less prone to scratching. However, it is more expensive than acrylic plastic and can be more difficult to work with.

- Glass: Glass is a transparent, rigid material that is often used as an alternative to acrylic plastic in applications where strength and transparency are important. However, it is heavier and more fragile than acrylic plastic, and is more prone to breaking or shattering.

- PETG: PETG, or polyethylene terephthalate glycol, is a transparent, lightweight plastic that is more impact-resistant than acrylic plastic. It is also UV stable and easy to work with. However, it is not as transparent as acrylic plastic and may yellow over time.

- Polystyrene: Polystyrene is a transparent, rigid plastic that is often used as an alternative to acrylic plastic in applications where transparency and light weight are important. However, it is not as strong as acrylic plastic and is more prone to scratching and yellowing.

- PVC: PVC, or polyvinyl chloride, is a transparent, rigid plastic that is often used as an alternative to acrylic plastic in applications where transparency and durability are important. However, it is not as strong as acrylic plastic and is more prone to scratching.

Overall, the best alternative to acrylic plastic will depend on the specific requirements of the application. It is important to consider factors such as strength, transparency, UV stability, and cost when selecting a suitable alternative.

Related Article: TOP 10 Best Acrylic Fish Tanks in 2023

Differences Between Acrylic and Plastic

Acrylic plastic, also known as polymethyl methacrylate (PMMA), is a type of plastic that is made from a combination of acrylic acid and a comonomer. It is a transparent, rigid plastic that is commonly used in a variety of products, such as windows, pipes, and as a replacement for glass.

Plastic is a broad term that refers to a wide range of synthetic or semi-synthetic materials that can be molded or shaped into a variety of forms. There are many different types of plastic, each with its own unique properties and uses.

Here are some key differences between acrylic plastic and plastic in general:

- Transparency: Acrylic plastic is known for its transparency, making it a popular choice for applications where visibility is important, such as windows and displays while plastic may not be as transparent or may have a more yellow or milky appearance.

- Strength: Acrylic plastic is not as strong as some other types of plastic, such as polycarbonate. It is more prone to breaking or cracking under impact or stress.

- UV stability: Acrylic plastic is resistant to UV light and does not yellow over time when exposed to UV radiation. Some other types of plastic may yellow or degrade when exposed to UV light.

- Scratch resistance: Also, acrylic plastic is more prone to scratching than some other types of plastic.

- Cost: Speaking of affordability, acrylic plastic is generally more expensive than other types of plastic.

- Recyclability: Acrylic plastic can be recycled, while some other types of plastic may not be as easily recyclable.

Frequently Asked Questions

Is acrylic better than plastic?

Acrylic plastic has several advantages over other types of plastic. It is lightweight, easy to work with, and can be molded into a variety of shapes and sizes. It is also a more environmentally friendly option, as it can be recycled and does not release harmful toxins when disposed of. However, it is not as strong as some plastic and is more prone to scratching and yellowing when exposed to UV light.

Is acrylic really plastic?

acrylic plastic is a type of plastic. It is a synthetic polymer made from a combination of acrylic acid and a comonomer. It is commonly used in a variety of products, such as windows, pipes, and as a replacement for glass.

Is a acrylic eco friendly?

Acrylic plastic can be a more environmentally friendly option compared to some other types of plastic. It is easily recyclable and does not release harmful toxins when disposed of. However, it is important to note that the manufacturing process for acrylic plastic can release fumes that may be harmful if inhaled in large quantities.

Is acrylic plastic toxic when heated?

Acrylic plastic is not toxic when it comes into contact with skin or when it is ingested. However, when heated, acrylic plastic can release fumes that may be harmful if inhaled. It is therefore important to use caution when working with acrylic plastic and to ensure that there is proper ventilation in the area

Conclusion

In conclusion, acrylic plastic is generally considered to be a safe and non-toxic material. It is not known to cause any harm when it comes into contact with skin or when it is ingested.

When heated, acrylic plastic can release fumes that may be harmful if inhaled. It is therefore important to use caution when working with acrylic plastic and to ensure that there is proper ventilation in the area.

Despite these potential risks, acrylic plastic has many useful properties and is widely used in a variety of applications. It is lightweight, easy to work with, and can be molded into a variety of shapes and sizes.